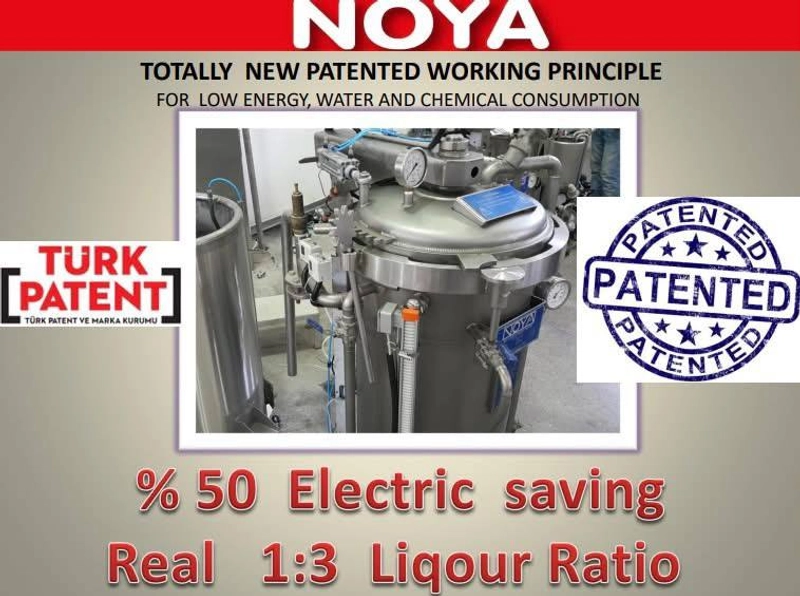

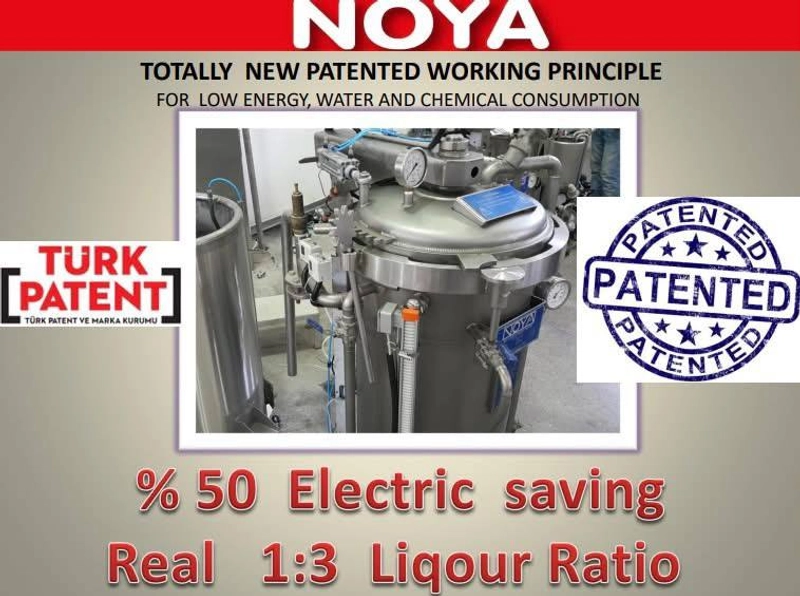

Máquina De Teñir Hilados (SISTEMA PATENTADO)

Precio del producto

Precio a consultar

Información de pago y envío

Máquina De Teñir Hilados (SISTEMA PATENTADO)

Noya Mekatronik

Detalles del producto

La máquina de teñido de hilo HT está diseñada en base a las últimas mejoras técnicas y tecnológicas relacionadas con el flujo de licor, la circulación del licor y la máxima eficiencia. La máquina se puede utilizar para procesar muchos tipos diferentes de materiales utilizando diferentes soportes adecuados, como bobinas, paquetes, manguitos, vigas, material suelto, tapas, etc.

Especificaciones

TECHNICAL ADVANTAGES Perfect dyeing results without having unlevelled dyeing effect for max. 2 kg bobbins in weight. Inside/outside and outside/inside two way flow without changing the direction of the snail pump motor. Short and fast heating times by efficient heat exchanger Dyeing capacity of min 50% and max. 100% with air pad system Perfect dyeing possibility on every pressure with differential pressure transmitter Repeatability by automation system Short dyeing times with the help of 100% reserve tank Liquor ratio in between 1:5 - 1:8 Single or double material carrier Heat exchanger in the circulation pipe line Rapid lid opening, closing, locking system Heavy duty stainless steel centrifugal pump with mechanical seal. DRYING PROCESS CONSISTS OF 3 SEQUENCES; HYDROEXTRACTION: replaces centrifugal operation and is done directly after loading of wet yarn carrier coming from dyeing machine. DRYING: Drying process starts automatically alter hydroextraction. The air is blown by the blower through heat exchanger for heating, heated at preset temperature according to yarn type and colour shade, flows at high speed through the yarn 1/0 direction, thereby transferring heat to the yarn and saturating with evaporated water. Duration of drying phase is preset on the base of air temperature at inlet and outlet of yarn packages 3 - YARN CONDITIONING: After the drying phase, air is circulated O/l direction in order to equalize residual humidity in yarn packages and reduce the temperature of the yarn. ADVANTAGES: No need of centrifuge hydro extractor. Loading and unloading is the waste time and also yarn packages may be damaged during loading /unloading. Process time is 50% to 70% shorter due to closed loop. Labour is dramatically reduced in the whole drying process.

Puerto de embarque

Turquía

Izmir Port

Sobre el proveedor

Visita la página del proveedorContactar con el proveedor

Más productos del proveedor

Producto similar

MÁQUINA DE BORDAR ...

Computarizado Enhebrador de agujas Ajuste de la agu...

Trading Networks ...

máquinas para hace...

Explore nuestra gama de máquinas de fabricación de bo...

MANUFATURA DE BOT...

Inversor vectorial...

Inversor vectorial de corriente de alto rendimiento s...

JIANGSU ROBIN KAN...

Limpiador con rodi...

Limpieza con rodillo Anilox. Nuestra serie RL (carga...

DCM Ultrasonic

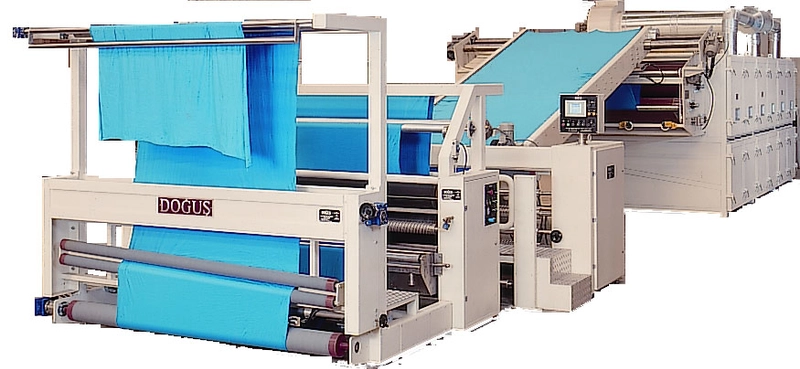

Secador Pin Chain ...

El objetivo principal del secador Pin Chain Air Relax...

Noya Mekatronik

Máquina de teñir h...

La máquina de teñido de hilo HT está diseñada en base...

Noya Mekatronik

Telar jacquard con...

Es adecuado para hilado de algodón, seda vaquera, sed...

Jiangxi Zhongbo I...

Máquina textil ZBm...

Adecuado para tejer algodón, cáñamo, fibras mezcladas...

Jiangxi Zhongbo I...

Bolsas de yute Dob...

El mayor rendimiento, diferente ancho de trabajo para...

Jiangxi Zhongbo I...

Máquina de tejer P...

Telar de tela industrial. Telar jacquard con estacas...

Jiangxi Zhongbo I...